LeydenJar Technologies

In 2016, the high-tech startup LeydenJar Technologies B.V. came to life as a spin-out venture of Energieonderzoek Centrum Nederland. LeydenJar is engaged in the development of pure silicon anode technology for the application in lithium-ion battery cells. The disruptive nature of LeydenJar’s technology has led them to collaborate regularly with some of the world’s largest EV and consumer electronics manufacturers.

The innovation: 100% silicon anodes

LeydenJar has developed a disruptive innovation that allows them to produce anodes that are 100% silicon and are able to remain stable. This is groundbreaking compared to current market leaders and leads to a battery with an energy density that is 70% higher than what is currently used in the latest generation of Tesla’s and iPhone. This technology also does not affect other important battery factors such as charge rate, battery life, cost and safety.

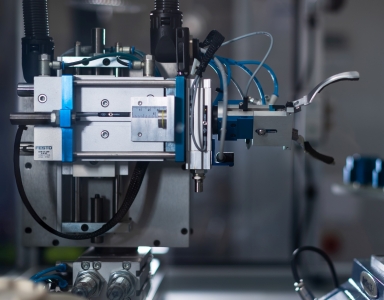

The project: Gen3 PECVD production technology

With its innovation of the silicon anode, LeydenJar has managed to develop a more efficient and sustainable battery. They will now produce this innovation in a more sustainable and cost-efficient way using the Gen3 PECVD installation (based on Plasma Enhanced Chemical Vapour Depostion, PECVD). To further develop, demonstrate, validate and scale up this installation, they applied for the Dutch Demonstration Energy and Climate Innovation (DEI+) scheme.

The purpose of this DEI+ demonstration project is to demonstrate that the silicon anode foil can be produced cost-effectively in the Gen3 installation. The demonstration project also aims to demonstrate that there is an 85% reduction in CO2 emissions in the total production process compared to regular lithium battery production processes. This proves that energy efficiency and CO2 reduction can be achieved! With the realisation of this innovation and installation, LeydenJar will gain a foothold in the global battery market.

Hezelburcht’s role: DEI+ subsidy

Hezelburcht has supported LeydenJar in successfully applying for the DEI+ subsidy. This was granted because of demonstrable investments in innovative and energy-efficient technologies. With their installation, they can produce anodes on a large scale with an energy density 70% higher than conventional (hybrid) graphite anodes, which also emits 85% less CO2 than the current production method.

Hezelburcht has guided us through the entire application process for the DEI+. Thanks to Hezelburcht’s knowledge and experience of the grant and the application procedure, we were able to receive a great amount of funding. The DEI+ grant has also contributed to the realisation of our last investment round. We have experienced the cooperation as very pleasant and we will definitely continue working with Hezelburcht for follow-up projects - LeydenJar Technologies